Informationen zu Crown Cork & Seal: Unterschied zwischen den Versionen

Rb (Diskussion | Beiträge) |

Rb (Diskussion | Beiträge) |

||

| Zeile 13: | Zeile 13: | ||

|} | |} | ||

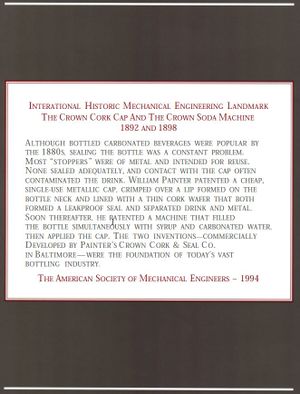

Quelle: American Society of Mechanical Engineering, 1994 | Quelle: American Society of Mechanical Engineering, 1994 | ||

| + | |||

| + | |||

| + | Crown has a long history of leading the industry with innovative packaging technology. | ||

| + | |||

| + | It is where we started in 1892 when our founder, William Painter, invented a better way to package soft drinks and beer. Painter's vision revolutionized the bottling industry. His ingenuity, and the leadership of those who came after him, helped to build Crown Holdings, Inc. into the world-class company it is today. | ||

| + | |||

| + | It is no wonder that, after over 100 years of growth and diversification, innovation has remained at the core of what we do every day. From that first ‘crown cork’ to our ground-breaking 360 End® beverage end to today's advanced shaping technology, Crown has led the way. | ||

| + | 1892 – A New Industry | ||

| + | |||

| + | Inventor William Painter patents the 'crown cork' and starts the Crown Cork & Seal Company of Baltimore. | ||

| + | 1898 – Automation | ||

| + | |||

| + | Painter introduces the first foot-powered syruper-crowner, allowing a good operator to fill and cap 24 bottles a minute. | ||

| + | 1906 – Early Expansion | ||

| + | |||

| + | By the time Painter dies in 1906, Crown has greatly expanded its manufacturing base to include Europe, South America and Asia Pacific. | ||

| + | 1919 – World War I | ||

| + | |||

| + | In the face of Prohibition, Crown begins shifting production from beer to soft drinks. | ||

| + | 1927 – New Impetus | ||

| + | |||

| + | Charles McManus, who patented Nepro Cork, a substitute for natural cork, merges the New Process Cork Company into Crown Cork & Seal Company, Inc. Net sales reach $11 million. | ||

| + | 1930 – New Speeds | ||

| + | |||

| + | Crown introduces high-speed, 3-piece bodymaking, revolutionizing the canmaking process. | ||

| + | 1936 – Moving into Tin Cans | ||

| + | |||

| + | Crown acquires the Acme Can Company of Philadelphia and enters the tin can business. | ||

| + | 1937 – The Crowntainer | ||

| + | |||

| + | Crown perfects the electrolytic tin plating process and introduces the Crowntainer, a 2-piece necked-in steel can sealed with a crown. | ||

| + | 1941 to 1945 – The Tin Can Goes to War | ||

| + | |||

| + | Crown shifts its production to war products and receives a government citation for the development of a gas mask canister. Crown also introduces the Kork-N-Seal, the Pour-N-Seal and the Merit Seal. | ||

| + | 1952 – Spra-tainer | ||

| + | |||

| + | Crown introduces the Spra-tainer, a lightweight, two-piece aerosol can for the food, personal care, household and insecticide markets. | ||

| + | 1957 – Turnaround | ||

| + | |||

| + | During difficult times, John Connelly takes over the presidency at Crown and pares down the organization, implementing stringent economies that help the company to recover. | ||

| + | 1958 – New Headquarters | ||

| + | |||

| + | Crown moves its corporate headquarters from Baltimore to Philadelphia. | ||

| + | 1960 – From Beer to Soft Drinks | ||

| + | |||

| + | Crown starts designing equipment specifically to meet the needs of soft drink producers and gains considerable market share in the United States. | ||

| + | 1968 – New Closure | ||

| + | |||

| + | Crown develops the first all-plastic closure for carbonated soft drinks. | ||

| + | 1969 – Steel Beverage Cans | ||

| + | |||

| + | Crown introduces the Drawn-N-Ironed, a two-piece steel alternative to the aluminum can, which rapidly becomes a hit product | ||

| + | 1970s – Financial Strength | ||

| + | |||

| + | Connelly focuses on international growth and repurchases preferred and common stock; earnings per share grow above industry averages. | ||

| + | 1970 – Audible Safety | ||

| + | |||

| + | Crown debuts metal vacuum closures featuring a safety button that provides an audible indication of pack safety. | ||

| + | 1976 – Flame Curing | ||

| + | |||

| + | Crown develops a patented flame-curing process that cures can coatings by direct flame impingement in less than one second. | ||

| + | 1977 – Foreign Expansion | ||

| + | |||

| + | Crown becomes one of the world’s leading producers of cans and crowns overseas, operating 60 foreign plants. Net sales reach $1 billion. | ||

| + | 1980 – New Innovations | ||

| + | |||

| + | Crown uses compartmentalized packages, such as piston and bag-in-can, to extend its range of aerosol applications. New full-aperture easy-open ends provide simplified opening and exceptional abuse resistance. Crown also introduces spin-necking, allowing for the production of lighter weight containers. | ||

| + | 1982 – High Impact Decoration | ||

| + | |||

| + | Crown introduces reprotherm, a patented sublimation-dye-transfer process for photographic quality decoration, for beverage cans. | ||

| + | 1984 – STEP & Petainer | ||

| + | |||

| + | Crown introduces PET/metal containers for food and beverage products. | ||

| + | 1985 – New Processes | ||

| + | |||

| + | Crown develops the external base profile reforming process to allow lighter base weight metal to be used on aluminum beverage cans while controlling buckle and growth. | ||

| + | 1986 – EOLE™ | ||

| + | |||

| + | Crown launches the EOLE™ brand of full-aperture easy-open ends, optimizing the convenience packaging. | ||

| + | 1988 – OXBAR | ||

| + | |||

| + | Crown develops oxygen scavenger technology (OXBAR) for use in PET containers to prolong the shelf life of sensitive products like beer. | ||

| + | 1989 – Acquisition Mode | ||

| + | |||

| + | Crown begins a series of acquisitions, increasing sales from $1.9 billion in 1989 to over $8 billion by 1997. | ||

| + | 1990 – Consolidation Begins | ||

| + | |||

| + | Crown acquires major portions of former industry leader Continental Can Company and becomes the North American packaging leader. The company introduces a new blowforming process to increase the shelf differentiation and brand recognition of containers. Meanwhile, new PT Plus closures debut that provide greater tamper evidence and Crown launches its Ideal Closure® – a polymer/metal hybrid that significantly reduces opening forces. | ||

| + | 1992 – Getting into Plastics | ||

| + | |||

| + | Crown acquires CONSTAR International, a world leader in PET plastic containers for the beverage, food and household markets. | ||

| + | 1996 – Creating a World Packaging Leader | ||

| + | |||

| + | Crown acquires CarnaudMetalbox, Europe's leading manufacturer of metal and plastic packaging, and becomes the world's packaging leader. | ||

| + | 1996 – New Digs | ||

| + | |||

| + | Crown’s global headquarters opens at a new location in Philadelphia. | ||

| + | 2000 – Introducing SuperEnd® | ||

| + | |||

| + | Crown unveils the revolutionary SuperEnd® beverage end technology. In addition, integrated weld monitoring is produced to improve the efficiency and quality of 3-piece canmaking. | ||

| + | 2001 – PealSeam™ | ||

| + | |||

| + | Crown’s new PeelSeam™ peelable ends enhance the openability of food products. | ||

| + | 2002 – CONSTAR IPO | ||

| + | |||

| + | Crown completes the sale of 89.5% of its shares in CONSTAR through an Initial Public Offering. The company also introduces bowl-shaped cans for a wide range of food applications including salads and desserts. | ||

| + | 2003 – Refinancing | ||

| + | |||

| + | Crown completes a $3.2 billion refinancing plan and forms Crown Holdings, Inc. as a new public holding company. | ||

| + | 2004 – High Spirits | ||

| + | |||

| + | Crown introduces injection-molded corks for spirits products. | ||

| + | 2005-6 – Trimming Assets | ||

| + | |||

| + | Crown sells its Global Plastic Closures and Cosmetics Packaging businesses. The company also introduces easy-open metal paint cans. | ||

| + | 2007 – EasyLift® | ||

| + | |||

| + | Crown sets a new standard in convenience packaging with the debut of its Easylift® easy-open ends. The company also introduces shaped food cans for every day luxury goods such as soup and coffee. In the beverage world, Crown unveils its Pictoris™ high quality print solution for use on aluminum cans. | ||

| + | 2008 – EarthSafe™ Dispensing System | ||

| + | |||

| + | Crown introduces the EarthSafe™ Dispensing System, an innovative and environmentally-responsible package that replaces hydrocarbons with compressed air as the propellant. | ||

| + | 2010 – The 360 End® | ||

| + | |||

| + | Crown launches the 360 End® for the 2010 FIFA World Cup tournament – the entire lid can be removed, turning the can itself into a drinking cup. This marks the first of many applications of this technology around the world. | ||

| + | 2011 – Leading the Way in Sustainability | ||

| + | |||

| + | Crown publishes its inaugural Sustainability Report based upon fiscal years 2007 through 2010. | ||

| + | 2011 – New Technologies | ||

| + | |||

| + | Crown unveils the new Orbit® Closure, a revolutionary closure that is twice as easy to open as standard twist-off caps, and HoloCrown™, a unique holographic foil technology. | ||

| + | 2013 – Global Vent™ | ||

| + | |||

| + | Crown introduces Global Vent™, a dual aperture beverage end that offers a smoother pour and an enhanced experience for consumers. | ||

| + | 2014 – A Time of Growth | ||

| + | |||

| + | Crown purchases Mivisa Envases, SAU and enters into an agreement to acquire EMPAQUE, significantly enhancing the company’s strategic position regionally and globally. | ||

| + | Quelle: www.crowncork.com | ||

Version vom 29. Juli 2018, 10:20 Uhr

Quelle: American Society of Mechanical Engineering, 1994

Crown has a long history of leading the industry with innovative packaging technology.

It is where we started in 1892 when our founder, William Painter, invented a better way to package soft drinks and beer. Painter's vision revolutionized the bottling industry. His ingenuity, and the leadership of those who came after him, helped to build Crown Holdings, Inc. into the world-class company it is today.

It is no wonder that, after over 100 years of growth and diversification, innovation has remained at the core of what we do every day. From that first ‘crown cork’ to our ground-breaking 360 End® beverage end to today's advanced shaping technology, Crown has led the way. 1892 – A New Industry

Inventor William Painter patents the 'crown cork' and starts the Crown Cork & Seal Company of Baltimore. 1898 – Automation

Painter introduces the first foot-powered syruper-crowner, allowing a good operator to fill and cap 24 bottles a minute. 1906 – Early Expansion

By the time Painter dies in 1906, Crown has greatly expanded its manufacturing base to include Europe, South America and Asia Pacific. 1919 – World War I

In the face of Prohibition, Crown begins shifting production from beer to soft drinks. 1927 – New Impetus

Charles McManus, who patented Nepro Cork, a substitute for natural cork, merges the New Process Cork Company into Crown Cork & Seal Company, Inc. Net sales reach $11 million. 1930 – New Speeds

Crown introduces high-speed, 3-piece bodymaking, revolutionizing the canmaking process. 1936 – Moving into Tin Cans

Crown acquires the Acme Can Company of Philadelphia and enters the tin can business. 1937 – The Crowntainer

Crown perfects the electrolytic tin plating process and introduces the Crowntainer, a 2-piece necked-in steel can sealed with a crown. 1941 to 1945 – The Tin Can Goes to War

Crown shifts its production to war products and receives a government citation for the development of a gas mask canister. Crown also introduces the Kork-N-Seal, the Pour-N-Seal and the Merit Seal. 1952 – Spra-tainer

Crown introduces the Spra-tainer, a lightweight, two-piece aerosol can for the food, personal care, household and insecticide markets. 1957 – Turnaround

During difficult times, John Connelly takes over the presidency at Crown and pares down the organization, implementing stringent economies that help the company to recover. 1958 – New Headquarters

Crown moves its corporate headquarters from Baltimore to Philadelphia. 1960 – From Beer to Soft Drinks

Crown starts designing equipment specifically to meet the needs of soft drink producers and gains considerable market share in the United States. 1968 – New Closure

Crown develops the first all-plastic closure for carbonated soft drinks. 1969 – Steel Beverage Cans

Crown introduces the Drawn-N-Ironed, a two-piece steel alternative to the aluminum can, which rapidly becomes a hit product 1970s – Financial Strength

Connelly focuses on international growth and repurchases preferred and common stock; earnings per share grow above industry averages. 1970 – Audible Safety

Crown debuts metal vacuum closures featuring a safety button that provides an audible indication of pack safety. 1976 – Flame Curing

Crown develops a patented flame-curing process that cures can coatings by direct flame impingement in less than one second. 1977 – Foreign Expansion

Crown becomes one of the world’s leading producers of cans and crowns overseas, operating 60 foreign plants. Net sales reach $1 billion. 1980 – New Innovations

Crown uses compartmentalized packages, such as piston and bag-in-can, to extend its range of aerosol applications. New full-aperture easy-open ends provide simplified opening and exceptional abuse resistance. Crown also introduces spin-necking, allowing for the production of lighter weight containers. 1982 – High Impact Decoration

Crown introduces reprotherm, a patented sublimation-dye-transfer process for photographic quality decoration, for beverage cans. 1984 – STEP & Petainer

Crown introduces PET/metal containers for food and beverage products. 1985 – New Processes

Crown develops the external base profile reforming process to allow lighter base weight metal to be used on aluminum beverage cans while controlling buckle and growth. 1986 – EOLE™

Crown launches the EOLE™ brand of full-aperture easy-open ends, optimizing the convenience packaging. 1988 – OXBAR

Crown develops oxygen scavenger technology (OXBAR) for use in PET containers to prolong the shelf life of sensitive products like beer. 1989 – Acquisition Mode

Crown begins a series of acquisitions, increasing sales from $1.9 billion in 1989 to over $8 billion by 1997. 1990 – Consolidation Begins

Crown acquires major portions of former industry leader Continental Can Company and becomes the North American packaging leader. The company introduces a new blowforming process to increase the shelf differentiation and brand recognition of containers. Meanwhile, new PT Plus closures debut that provide greater tamper evidence and Crown launches its Ideal Closure® – a polymer/metal hybrid that significantly reduces opening forces. 1992 – Getting into Plastics

Crown acquires CONSTAR International, a world leader in PET plastic containers for the beverage, food and household markets. 1996 – Creating a World Packaging Leader

Crown acquires CarnaudMetalbox, Europe's leading manufacturer of metal and plastic packaging, and becomes the world's packaging leader. 1996 – New Digs

Crown’s global headquarters opens at a new location in Philadelphia. 2000 – Introducing SuperEnd®

Crown unveils the revolutionary SuperEnd® beverage end technology. In addition, integrated weld monitoring is produced to improve the efficiency and quality of 3-piece canmaking. 2001 – PealSeam™

Crown’s new PeelSeam™ peelable ends enhance the openability of food products. 2002 – CONSTAR IPO

Crown completes the sale of 89.5% of its shares in CONSTAR through an Initial Public Offering. The company also introduces bowl-shaped cans for a wide range of food applications including salads and desserts. 2003 – Refinancing

Crown completes a $3.2 billion refinancing plan and forms Crown Holdings, Inc. as a new public holding company. 2004 – High Spirits

Crown introduces injection-molded corks for spirits products. 2005-6 – Trimming Assets

Crown sells its Global Plastic Closures and Cosmetics Packaging businesses. The company also introduces easy-open metal paint cans. 2007 – EasyLift®

Crown sets a new standard in convenience packaging with the debut of its Easylift® easy-open ends. The company also introduces shaped food cans for every day luxury goods such as soup and coffee. In the beverage world, Crown unveils its Pictoris™ high quality print solution for use on aluminum cans. 2008 – EarthSafe™ Dispensing System

Crown introduces the EarthSafe™ Dispensing System, an innovative and environmentally-responsible package that replaces hydrocarbons with compressed air as the propellant. 2010 – The 360 End®

Crown launches the 360 End® for the 2010 FIFA World Cup tournament – the entire lid can be removed, turning the can itself into a drinking cup. This marks the first of many applications of this technology around the world. 2011 – Leading the Way in Sustainability

Crown publishes its inaugural Sustainability Report based upon fiscal years 2007 through 2010. 2011 – New Technologies

Crown unveils the new Orbit® Closure, a revolutionary closure that is twice as easy to open as standard twist-off caps, and HoloCrown™, a unique holographic foil technology. 2013 – Global Vent™

Crown introduces Global Vent™, a dual aperture beverage end that offers a smoother pour and an enhanced experience for consumers. 2014 – A Time of Growth

Crown purchases Mivisa Envases, SAU and enters into an agreement to acquire EMPAQUE, significantly enhancing the company’s strategic position regionally and globally. Quelle: www.crowncork.com