Informationen zu L&G

1915.

Description

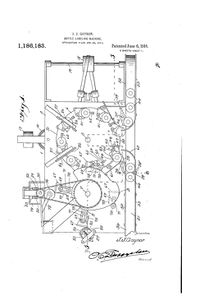

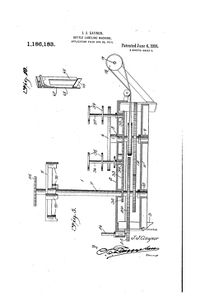

J. J. 'GAYNOR BOTTLE LABELING MACHINE.

APPLICATION FILED APR. 30. 1915.

Patented June 6, 1916.

8 SHEETSSHEET I.

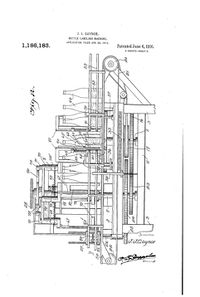

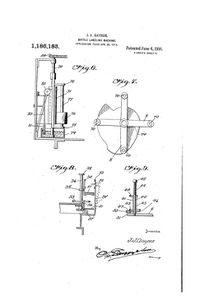

11% 1 0 II E J. J. GAYNOR.

BOTTLE LABELING MACHINE.

APPLICATION FILED APR. 30. 1915.

l 1 86, 1 83 Patented June 6, 1916.

8 SHEETSSHEET 2.

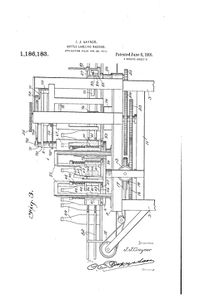

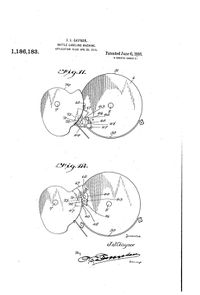

J. J. UAYNOR.

BOTTLE LABELING MACHINE.

APPLICATION FILED APR.30.1915.

Patented June 6, 1916.

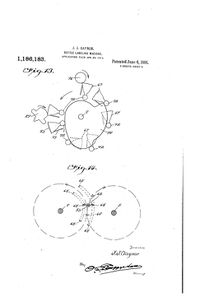

8 SHEETSSHEET 3i O flfaaynor 1.]. GAYNOR.

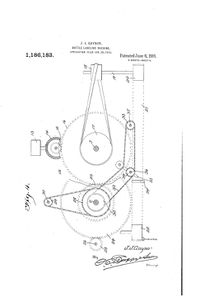

BOTTLE LABELING MACHINE.

APPLICATION FILED APR. 30.1915.

Patented June 6, 1916.

8 SHEETSSHEET 4.

1.1. GAYNOR.

BOTTLE LABELING MACHINE.

APPLICATION man APR. 30. 1915.

1 1 86, 183 Patented J 1 1116 6, 1916.

8 SHEETS-SHEET 5.

\Q (8% 1 IQ w Q g u grvucnkvc Jzfaaynor Q J. J. GAYNOR. BOTTLE LABELING-MACHINE. APPLICATION FILED APR. 30. l9i5.

1,186,183, Patented June 6,1916.

8 SHEETS-SHEET 6.

II VIIIIIIIIIIIIIII\I III/ I. J. GAYNOR. I BOTTLE LABELING MACHINE. APPLICATION FILED APR. 30. 1915.

Patented June 6, 1916.

a SHEETSSHEET I:

J. J. GAYNOR. BOTTLE LABELING MACHINE.

APPLICATION FILED APR. 30. 1915.

Patented June 6, 1916.

8 SHEETSSHEET 8- JJGQ W citizen of the United States, residing at In- UNITED STATES PATENT OFFICE.

- JOHN J. GAYNoRL, or INDIANAPOLIS, INDIANA, ASSIGNOR. To THE L. a e. MANUFAC- -TURING comPANY, orINDIANAPoLIs, INDIANA, A CORPORATION.

BOTTLE-LABELING MACHINE.

Specification of Letters Patent.

Patented June 6, 1916.

To all whom it may concern Be it known that I, JOHN J. GAYNOR, a

dianapolis, in the county of Marion and State of Indiana, have invented certain new and useful Improvements in Bottle-Labeling Machines; and. I do declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had 'to the accompanyingdrawings, and to the letters and figures of reference marked thereon, which form a part of this specification.

This invention relates to bottle labeling machines and has for its object to provide j a machine for applying and affixing labels to' bottles in such manner that the bottles ing, but are delivered from the machine with are not handled during the process of labelsitioned thereon.

A further object of the invention is to provide a bottle labeling machine which by the'label or labels properly applied and poreason of its design, construction and arrangement of parts can be operated at a high rate of speed, and in which breakage is reduced to a minimum.

A further object of the invention is to provide a bottle labeling machine in-which the movements of the labeling devices and the bottles are rotary, as distinguished from reciprocating or oscillatory movements, so that a faster, more eflicient and more durable machine is provided.

A further object of the invention is to provide a bottle labeling machine which by reasonof the rotary-movements of the parts embodies a minimum number of elements, thus producing a machine of s mple construction,.noiseless and extremely compact.

A further object of theinvention is to provide a bottle labeling machine by means of which-oneor more labels can be simul-' taneously applied and aflixed to bottles successively.

With these andIother objects in view the invention consists in the novel construction of the arrangement for delivering -thebottles to and receiving the bottles from the rotating table. I i,

The invention furtherconslsts 1n the novel construction and arrangement of the bottle receiving and holding elements on the rotating table.

The invention further consists in the novel arrangement and construction of the label wib iing device associated with the rotating ta e.

The invention further consists in the novel construction and arrangement of the bottle labeling devices, and in the mechanical movement of the said bottle labeling devices considered separately and also in connection with the bottle engaging and retaining devices on the rotating table.

The invention further consists in the novel construction and arrangement of the paste applying mechanism.

The invention further consists in the novel construction and arrangement of the label holding box.

The invention further consists in certain of the driving mechanismand gearing. Fig.

5 is a vertical longitudinal sectional view through the stationary table taken on line 5-5 of Fig. 1. Fig. 6 is a detail elevation of the paste applying mechanism. Fig. 7 is a bottom plan view of the label mechanism actuating-cam, illustrating also the spider in which the label applying devices are pivoted. Fig. 8 is-a vertical transverse fragmentary sectional view of the bottle stop mechanism taken on line 8-8 of Fig. 1.

Fig. 9 is a vertical sectional view through one of the bottle holding devices, the rotating table .being shown in fragmentary section. Fig. 10 is a perspective view of one -of the label afiixers. Fig. 11 is a plan view of the label mechanism actuating cam and rotating table, illustrating one of the bottle 10 labeling devices in theposition it assumes just prior tothe application of a, label to a bottle. Fig. 12 is a similar view, illustrating the position of these parts just after a label has been applied to a bottle. Fig. 13 is a diagrammatic view illustrating the several positions that each bottle labeling device assumes upon each full revolution thereof, and Fig. 14 is a diagrammatic view illustrating the position of one of the bottle labeling devices and one of the bottle engaging and label applying fingers in section. in full lines at the time that said bottle engaging and label applying finger is receiving the label from one of the label carrying devices, and also illustrating in dotted lines the position of these parts just prior to the reception of the label from the label carrying device and in dotted lines the position of these parts just after the bottle holding and label applying finger has received the label from the label carrying device and has applied same to a bottle.

Like numerals of reference indicate the same parts throughout the several figures, in which 1 indicates the machine which comprises a stationary table 2 having suitable supporting frame-work 3, said table 2 forming a bearing for the rotating shaft 5 carrying the rotating table 6, the said stationary table 2 also forming a bearing for the rotating shaft 7 carrying the rotating spider 8 of the label applying devices. Both of said shafts 5 and 7 are journaled at 9 and 10 in a lower plate 11 (Fig. 5) between which plate 11 and star tionary table 2 the gearing mechanism 12 is disposed in the manner as shown in Fig. 5.

Referring now to Fig. 4 which illustrates the driving and gearing mechanism diagrammatically it will be seen that power is transmitted to the machine preferably through a belt pulley 13 which through the medium of beveled gearing 14 and a pinion 15 drives the large gear wheel 16 secured on the rotating table shaft 5. Fastened to said shaft 5 is a pulley l7 belted to a drum 18 on a shaft 19 carrying one of the drums 20 of the bottle conveying belt or apron 21, said bottle conveying belt or apron 21 being endless and passing over a drum 22 at the opposite end of the machine. Meshing with the large gear wheel 16 is a smaller gear wheel 23 of a ratio of 2 to 1, the said gear wheel 23 driving the rotating shaft 7 of the labeling devices, and also drivin a large gear wheel 24 meshing with a sma 1 gear wheel 25 secured on the shaft 26 of the rotating label box 27. The shaft 7 also drives a sprocket 28 chained to a smaller sprocket 29 on the shaft 30 carrying the paste receiving roll 31 (Fig. 6), while a sprocket 32 is also driven by the shaft 7 said sprocket carrying a chain 33 passing around sprockets 34 and 35 mounted on shafts 36 and 37 which carry the two pointed star wheels 38 and 39 (Fig. 1). As before stated the gearing mechanism with the exception of the large sprocket 28 is mounted under the stationary table 2 of the machine.

Referring now particularly to the rotating table 6 it will be seen that the same is. provided with a plurality of vertical shafts 40, one of which is illustrated in Fig. 9, and upon each shaft 40 is the bottle receiving mechanism 41 which mechanism includes an upper concaved member or finger 42 and a lower member or finger 43, the concavity .of said members or fingers 42 and 43 conforming to the periphery of the bottle 44, as will .be a parent from an inspection of Fig. 1.

Carried on the sleeve 45 of the fingers or members 42 and 43 is a bottle receiving platform 46 (Fig. 1) to which platform asmall roller 47 (Figs. 1 and 9) is secured. Mounted on each of the vertical spindles or shafts 40 under a head 48 is a spiral spring 49 which is attached to the shaft 40 at its upper end and to the sleeve 41 at its lower end, the tension of said spring 49' being to carry and retain the bottle holding fingers or members 42 and 43 and the bottle supporting platform 46 in their innermost position upon the face of the rotating table 6. Associated with the rotating table 6 and in position shown in Fig. 1 is a rail or cam 50 which is in the path of movement of the small roller 47 on each of the bottle receiving platforms 46, each of said rollers 47 normally extending beyond the periphery 51 of the rotating table 6 in the manner as shown in Fig. 1. Upon rotation of the rotary table 6 the small rollers 47 are successively engaged by the rail or cam 50 in the manner as shown in Fig. 1, which causes the bottle enga .g and holding fingers or members42 an 43 and the bottle receiving platforms 46 to be swung outwardly on their spindle or shaft 40 in the manner as is illustrated in Fig. 1 for a purpose which will now be described.

Referring now particularly to the bottle conveying belt or apron 21 (Fig. 1) it will be seen that a suitable railing 52 is arranged along the inner side of the belt or apron 21,

the outer edge of said belt'or apron, so that the bottles when placed upon the receiving end 54 of the said belt or apron are prop-- erly conveyed thereon. As the bottles are conveyed on the receiving end. of the apron 21 to the position shown in F ig. 1 their progress is interrupted by a stop 54' which 1s shown in detail in Fig. 8. The shaft 36 which carries the upper and lowerreceiving star wheel 38 is also provided with and carries a rotating arm 55 which trips a lever 56 fulcrumed at 57 and carrying the stop 54', the upper end 59 of which is bent inand a similar railing'53 is arranged along I wardly over the belt or apron. 21 in the path of movement of the bottles 44.. Upon stop 54' into position shown in dotted lines in Fig. 8, thus allowing one bottle to be conveyed beyond the said stop 54: and into position shown in Fig. 1. The said bottle is then positioned to be engaged by the upper and lower star wheels 38, and to be carried thereby on to one of the bottle supporting platforms 46, which by the mechanism herebefore described has been swung beyond the periphery of the rotating table 6 into position to receive the bottle from the star wheels 38 in the manner as illustrated in Fig. 1, the outer rail 53 being curved inwardly at to facilitate the deposit of the bottle upon the said bottle receiving platform 16. I provide a leaf spring 61 in close association with the star wheels 38 as shown in Fig. 1 for the purpose of preventing accidental displacement of the bottle from its receiving platform -16 after the same has been deposited thereon by the star wheels 38. As the roller 47 on the bottle receiving platform 16 just receiving a bottle passes beyond the rail or cam 50 the spiral spring 19 (Fig. 9) swings the bottle receiving platform, the bottle and the fingers or members -12 and -13 inwardly over the rotating table 16, and causes the bottle to be brought into engagement with the bottle holding and label applying finger 62. Referring particularly to this element and to Fig. 2 it will be seen that the bottle engaging and label applying finger 62 is pivoted at 63 to a vertical staff or post 61 having thereon a leaf spring 65 for the purpose ofv imparting flexibility to the said finger 62, and from Fig. 2 it will be seen that each of the said fingers 62 is provided with an upper extension 65 and a lower extension 66 which are immediately in engagement with the bottle and which receive and apply the label or labels in a manner which will hereinafter be fully described. It will be understood from Fig. 1 that the bottle engaging and label applying finger 62 when engaging the bottle, effectually grips the same, holding the bottle in proper position upon the bottle receiving platform 46 and within the concaved bottle engaging and receiving fingers or members 42 and 43, in the manner as illustrated in Fig. 1.

Referring now to the labeling mechanism and particularly to Figs. 1, 5 and 7 it will be seen that the spider 8 which is mounted on the rotating shaft 7 carries on each of its 1 four arms a bifurcated or forked label conveying member 67, the same being centrally cut away in the manner as shown in Fig. 10, so as to present two depending arms or fingers 68. each of said label conveying members 67 being mounted on a shaft 69 (Fig. 2) which is journaled in the bearings 70 in the spider 8. and which is provided on its upper end with a crank 71 mounting a. roller 72, each of the supports 72 for the label conveying members 67 being provided with a spiral spring 73 to normally hold said label conveying members 62 in their outermost extended position. Arranged stationary relative to the rotating shaft 7 and spider 8 is a cam 7-1 which as will appear from Figs. 1 and 2 is disposed in the path of movement of the rollers 72, so that upon rotation of the said shaft 7, spider 8 and label conveying devices 67 the rollers 72 will engage the cam 71, causing said rollers to be moved out of their normal position, and by means of the cranks 71 swing the bifurcated label conveying devices 67 into the several positions indicated diagrammatically in Fig. 13. It will further appear from Fig. 10 that each of the bifurcated label conveying devices 67 is provided with a leaf spring 7 5 for the purpose of engaging the bottle to prevent displacement thereof at the instant that the bottle engaging and label afiixing finger 62 is receiving the label from the label conveying member 67. As will appear from Fig. 13 which as before stated illustrates the several positions assumed by each label conveying device 67 upon each full revolution thereof it will be seen that for a portion of each revolution of each of the label conveying devices 67 its roller 72 is out of engagement with the cam 74. While in this position which can be said to be the initial position of the label conveying device 67, the same comes into rolling contact with the paste distributing roll 76 which roll is mounted on a shaft 77 carried in an upper and lower bracket 7 8 which through a suitable connection is swung on the rotating shaft 30 driven by the sprocket wheel 29, which rotating shaft 30 carries the paste feed roll 31 mounted centrally of the paste box 79 into which a belt 80 on pulleys 81 and 82 pass from the paste box to and around the upper portion of the paste feed roll 31. The paste distributing roll 7 6'being in rolling contact with the paste feed roll 31 receives its paste therefrom, the excess paste dropping from the feed roll 31 back into the paste box 79. The said distributing paste roll 76 being in the path of movement of each of the label conveying devices 67 and being rotated by the said paste feed roll 31 in a direction opposite to that of the label conveying devices, a rolling engagement or contact is effected between each of the label conveying devices 67, and the paste distributing roll 76 to distribute on the face of each label conveying device 67 a suflicient quantity of paste for insuring a proper and permanent adherence of the label to the bottle. As each of the label conveying devices 67 receives its paste from the paste distributing roll 76 it passes on to its next position, as illustrated in Figs. 1 and 13, where it comes into rolling contact with a label 83 in the label box 27, which label box is rotating in a direction opposite to that of the label conveying members 67, so that as each member 67 with paste applied thereto rolls over the outermost label 83 in the label box 27 said outermost label adheres to the'face of the label conveying member 67, and the label is removed from the box in a manner which will be perfectly apparent from an inspection of Fig. 1.

Referring particularly to the label box 27 it will be seen that the same embodies a spring actuated follower 8i and guide pieces 85 between which the labels 83 are disposed and held in proper operative position by the follower 84 in the manner as illustrated in Fig. 1. Shortly after the label conveying device 67 picks up its label from the label box 27 as just described, its roller 72 initially engages the cam 7 4:, and as the rotation progresses said label conveying device is swung successively into the positions shown in Fig. 13. It will be understood that by means of the gearing heretofore described the label conveying devices 67 and their rotating shaft 7 and spider 8 are all rotating at a ratio of 2 to 1 with relation to the rotary table 6, and while this particular ratio is not essential still I prefer as shown in the drawings to employ four label conveying devices 67 and eight bottle receiving platforms and fingers for the reception of eight bottles in the rotating table 6, so that upon a full revolution of the rotating table 6 each label conveying device 67 completes two full revolutions. p

Referring now to Figs. 1, 13 and 14 it will be seen from Fig. 1 that the bottle receiving platform 46 which is receiving a bottle and being held in an extended position by its roller 47 acting on the rail or cam 50, will be maintained in this extended position until the roller 47 reaches the end of the rail or cam 50 indicated by the letter A, and it will be seen that a considerable space is being maintained between the bottle 44 and its bottle engaging and label applying finger 62. Vhile said finger 62 is rotating with the table 6 one of the label conveying members 67 which for the purpose of description is indicated by the letter B is rotating at twice the speed, and as it is conveying a label and has been turned into position under the influence of the cam 7 4, said label conveying element 67 (B) overtakes the bottle engaging and label afiixing finger 62 straddling the same and causing said bottle engaging and label aflixing finger 62 to pass through the bifurcated portion and between each of the depending arms or fingers 68 (Fig. 10) so that the label which is being conveyed by the label conveying element 67 is deposited on the bottle engaging and label applying finger 62, which operation is illustrated diagrammatically in Fig. 14:. As soon as the label has thus been deposited on the bottle engaging and label affixing finger 62 and by reason of its greater speed of rotation has moved beyond and away from said bottle engaging and label aliixing finger 62 which has now received the label, the roller 47 on the bottle receiving platform d6 passes oil of end A of the rail or cam 50,

and under the influence of the spiral spring the bottle and holding the same in' proper position thereon as the bottle progremes and passes through the label wiper 86, which as will appear from Figs. 1 and 2 comprises an upright structure 87 having a pair of flexible wipers which engage both sides of the label and smooth the same on the bottle. As will appear from Fig. 1 two of these label wipers 86 are illustrated, and I can of course employ as many as are necessary to properly wipe and smooth out the label, it being of course understood that these label wiping devices 86 are stationary with relation. to the rotating table 6, and that the bottles with their labels thereon are passed successively through the said wipers 86 until the roller 47 of each of the bottle receiving platforms -16 again comes in contact with the rail orcam'50, which again swings the bottle receiving platform and its bottle outwardly and beyond the periphery of the rotating table 6 where it is engaged by the delivery star wheels 39 and delivered again to the conveying belt or apron 21 in the manner as is illustrated in Fig. 1. As the bottle receiving platform -16 delivers its bottle to the belt or apron 21 it passes on and immediately receives another bottle from the bottle depositing star wheels 38.

From the above specification taken in connection with the accompanying drawings the construction and operation of the invention will be at once apparent to those skilled in the art, and while I have illustrated and described only the application of a single label to a bottle so as not to unduly complicate the illustration and description of the invention I wish it to be distinctly understood that by this same mechanism two labels can be simultaneously applied by the provision of a double label box, one above the other, and a. double paste feed roll, one above the other, so that the lower label as shown in the drawing will be deposited by the label conveying device 67 on the lower extension 66 of the bottle engaging and label depositing finger 62, and the upper label simultaneously deposited on the upper extension 65 of said bottle engaging and label depositing finger 62 so that both labels are simultaneously applied and afiixed to the bottle, and are of course simultaneously wiped and smoothed by the label wipers 86, and it is for this purpose that I have constructed the bottle engaging and label applying fingers 62 with the upper and lower extensions 65 and 66 thereon.

Having thus fully described the invention it is of course apparent that the same is susceptible to certain changes and alterations in the construction and arrangement of the parts, and I consider myself clearly entitled to all such changes and modifications as fall Within the limit and scope of the appended claims.

lVhat I claim as new and desire to secure by Letters Patent of the United States is- 1. A bottle labeling machine, including a horizontally disposed rotatable table, a plurality ofbottle receiving and engaging devices disposed thereon and rotatable therewith, a conveyer for conveying the bottle to and from said bottle receiving and engaging devices, means associated with said conveyer for depositing the bottle therefrom to said bottle receiving and engaging devices, means associated with said conveyer for deliveringthe bottles from said bottle receiving and engaging devices to said conveyer, a plurality of label conveying devices associated with said rotatable table, a paste feed roll arranged for'engagement by said label conveying devices, a rotatable label box arranged for engagement by said label conveying devices, the said bottle receiving and engaging devices including a bottle engaging and label affixing finger on said rotatable table to receive a label from said label conveying devices, and to affix the same to a bottle, and means arranged stationary with relation to said rotatable table for wiping the label so affixed to a bottle, substantially as described and for the purposes set forth.

2. A bottle labeling machine, including a rotatable table, a plurality of bottle receiving and engaging devices disposed thereon and rotatable therewith, a conveyer forconveying the bottles to and from said bottle receiving and engaging devices, means associated with said conveyer for depositing the bottle therefrom to said bottle receiving and engaging devices, means associated with said conveyer for delivering the bottles from said bottle receiving and engaging devices to said conveyer, a plurality of label conveying devices associated with said rotatable table, a

- paste feed roll arranged for engagement by said label conveying devices, a rotatable label box arranged for engagement by said label conveying devices, the said bottle receiving and engaging devices including a bottle engaging and label affixing finger on said rotatable table to receive a label from said label conveying devices andto afiix the same to a bottle, and means arranged stationary with relation to said rotatable table for wiping the label so aflixed to a bottle,

substantially as described and for the purposes set forth.

3. A bottle labeling machine, including a rotatable table, a series of bottle receiving and engaging devices arranged thereon and rotatable therewith, means for conveying bottles to and from said bottle receiving and engaging devices on said rotatable table, a series of label conveying devices associated with said rotatable table and said bottle receiving and engaging devices, means for distributing paste on said label conveying devices, means for holding a label to be engaged and received by said label conveying devices, said bottle receiving and engaging devices including a bottle engaging and label applying finger to receive the label from said label conveying devices and to apply the same to a bottle, and means arranged stationary with relation to said rotating table to wipe the labels so aifixed to a bottle, substantially as described and for the purposes set forth.

4. A'bottle labeling machine, including a rotatable table, a series of bottle receiving and engaging devices arranged thereon and rotatable therewith, means for conveying bottles to and from said bottle receiving and engaging devices on said rotatable table, a series of label conveying devices associated with said rotatable table and said bottle receiving and engaging devices, means for distributing paste on said label conveying devices, means for holding a label to be 'engaged and received by said label conveying devices, said bottle receiving and engaging devices including a bottle engaging and label applying finger to receive the label from said label conveying devices and to apply the same to a bottle, substantially as described and for the purposes set forth.

5. A bottle labeling machine, including a rotatable table, means for receiving and engaging a bottle carried on said table and rotatable therewitl1,means for conveying abottle to and from the bottle receivingand engaging means, a label conveying device associated with said rotatable table and the bottle receiving and engaging means, means for distributing paste on said label conveying device, means fordepositing a label on said label conveying device, said bottle receiving and engaging means including an element for receiving a labelfrom said label conveying device and for afiixing the same to a bottle, and means for wiping the label so affixed to a bottle, substantially as described and for the purposes set forth. v

6. A bottle labeling machine, including a rotatable table, means for receiving and engaging a bottle carried on said table and rotatable therewith, means for conveying a bottle to and from the bottle receiving and engaging means, a label conveying device associated with said rotatable table and the deliver a bottle, said bottle receiving and.

engaging means including a label aiiixing finger, means for delivering a bottle to and from said bottle receiving and engaging means, a label conveying device for receiving and conveying a label and for deposlting the same on said label aiiixing' finger to be aifixed thereby to a bottle and means for wiping the label so affixed.

8. A bottle labeling machine, including a rotatable table having means movably mounted thereon for receiving and engaging a bottle, means for moving said bottle receiving means into positions to receive and deliver a bottle, said bottle receiving and engaging means including a label afiixing finger, means for delivering a bottle to and from said bottle receiving and engaging means, a label conveying device for receiving and conveying a label and for depositing the same on said label atiixing finger to be aifixed thereby to a bottle.

9. A bottle labeling machine, including a rotatable table, a bottle receiving and engaging device movably mounted thereon and rotatable therewith. means for moving said bottle receiving device in position to receive a bottle, said bottle receiving and engaging device including a label 'aifixing finger, a label conveying device for receiving and conveying a label and for depositing the same on said label afiixing finger to be affixed thereby to a bottle and means for wiping a label so aflixed.

10. A bottle labeling machine, including a rotatable table, a bottle receiving and engaging device movably mounted thereon. and rotatable therewith, means for moving said bottle receiving device into position for receiving a bottle, said bottle receiving and engaging device including a label affixing finger, a label conveying device for receiving and conveying a label and for depositing the same on said label afifixing finger to be atiixed thereby to a bottle.

11. A bottle labeling device, including a rotatable table, a series of bottle receiving and engaging devices pivoted thereon and rotatable therewith, each of said bottle receiving and engaging devices including a 55 bottle engaging and label applying finger arranged stationary with relation to the rotatable table and rotatable therewith, a conveyer for conveying bottles to and from said rotatable table and means associated with said conveyer for delivering bottles therefrom to the said rotatable table and for depositing bottles thereon from said rotatable table, means associated with said rotatable table and in the path of movement of said bottle receiving and engaging devices to be engaged thereby to swing the same out of their normal position to receive a bottle from said conveyer and to deposit a bottle to said conveyer, a series of label conveying devices associated with said rotatable table, each of which includes a bifurcated label receiving and conveying member, means for distributing paste on said bifurcated label receiving and conveying member, label holding means for holding a label to be engaged and received by said bifurcated label receiving and conveying member, said bifurcated label receiving and conveying member meeting and straddling one of the said bottle engaging and label affixing fingers to deposit a label thereon while its associated bottle receiving and engaging device is being main tained in an outwardly swung position by the aforementioned means arranged in the path of movement of the bottle receiving and engaging devices, said bottle receiving and engaging devices including means for swinging its bottle inwardly of the rotatable table and into engagement with the said bottle engaging and label aflixingfinger to receive a label therefrom, and means for wiping the label so aiiixed.

12. A bottle labeling device, including a rotatable table, a series of bottle receiving and engaging devices pivoted thereon and rotatable therewith, each of said bottle re ceiving and engaging devices including a bottle engaging and label applying finger arranged stationary with relation to the rotatable table and rotatable therewith, a conveyer for conveying bottles to and from said rotatable table and means associated with said conveyer for delivering bottles therefromtothesaid rotatable table and for depositing bottles thereon from said rotatable table, means associated with said rotatable table and in the path of movement of said bottle receiving and engaging devices to be engaged. thereby to swing the same out of their normal position to receive a bottle from said conveyer and to deposit a bottle to said conveyer, a series of label conveying devices associated with said rotatable table, each of which includes a bifurcated label receiving and conveying member, label holding means for holding a label to be engaged and received by said bifurcated label receiving and conveying member, said bifurcated label receiving and conveying mem- 19?! meeting andstraddling one of the said.

bottle engaging and label afiixing fingers to deposit a label thereon while its associated bottle receiving and engaging device is being maintained in an outwardly swung position by the afore mentioned means arranged in the path of movement of the bottle receiving and engaging devices, said bottle receiving and engaging means including means for swinging its bottle inwardly of the rotatable table and into engagement with the said bottle engaging and label aflixing finger to receive a label therefrom.

13. A bottle labeling machine, including a rotatable table, a series of bottle receiving and engaging devices thereon and rotatable therewith, a bottle conveyer, means for swinging said bottle receiving and engaging devices outwardly of the said rotatable table to receive a bottle from and deposit a bottle on said conveyer, a series of cam actuated label receiving and conveying devices .each of which includes a bifurcated label receiving and conveying member, means for depositing paste on said member, means for depositing a label on said member, each engaging of said bottle receiving and engaging devices on said rotatable table including a bottle engaging and label affixing finger arranged stationary with relation to the rotatable table and rotatable therewith, the said bifurcated label receiving and conveying member with a label thereon meeting and straddling one of said bottle engaging and label afiixing fingers to deposit its label thereon while the said bottle receiving and engaging device is in an outwardly swung position, each of said bottle receiving and engaging devices including means for swinging the same inwardly of the said rotatable table and into engagement with its said bottle engaging and label affixing finger to receive the label deposited thereon by the said bifurcated label receiving and conveying member, and means for Wiping the label.

14. A bottle labeling machine, including a rotatable table, a series of bottle receiving and engaging devices thereon and rotatable therewith, a bottle conveyer, means for swinging said bottle receiving and engaging devices outwardly of the said rotatable table to receive a bottle from and, deposit a bottle on said conveyer, a series of cam actuated label receiving and conveying devices, each of which includes a bifurcated label receiving and conveying member, means for depositing-paste on said member, means for depositing a label on said member, each of said bottle receiving and engaging devices on said rotatable table including a bottle and label affixing finger arranged stationary with relation to the rotatable table and rotatable-therewith, the said bifurcated label receiving and conveying member with a label thereon meeting and straddling one of said bottle engaging and label afiixing fingers to deposit its label thereon while the said bottle receiving and engaging device is in an outwardly swung position, each of said bottle receiving and engaging devices including means for swinging the same inwardly of the said rotatable table and into engagement with its said bottle engaging and label afiixing finger to receive the label deposited thereon by the said bifurcated label receiving and conveying member.

15. A bottle labeling machine including a rotatable table and means for conveying bottles to and from the same, a series of bottle receiving and engaging devices pivot ally mounted on said rotatable table, each of said devices including a bottle engaging and label afiiXing finger arranged stationary with relation to the said rotatable table,

each of said bottle receiving and engaging Y devices including a platform and fingers conforming to the shape of a bottle, means for swinging said bottle receiving and engaging device's outwardly of the said rotating table and out of engagement with the said bottle engaging and label afiixing finger, a series of cam actuated pivoted label receiving and conveying devices, each of which includes a bifurcated label receiving and conveying member, means for depositing paste on said member and means for depositing a label thereon to be conveyed thereby to one of said bottle engaging and label afiixing fingers, said bifurcated label receiving and conveying member meeting and straddling the said bottle engaging and label afiixing finger to deposit its label thereon while the said bottle receiving and engaging device is in an outwardly swung position and means associated with each of said bottle receiving and engaging devices for swinging the same and its bottle inwardly of the said rotating table and into engagement with its said bottle engaging and label applying finger to receive a label therefrom, and means for wiping the label so received on the bottle.

16. .A bottle labeling machine including a rotatable table and means for :onveying bottles to and from the same, a series of bottle receiving and engaging devices pivotally mounted on said rotatable table, each of said devices including a bottle engaging and label aflixing finger arranged stationary with relation to the said rotatable table, each of said bottle receiving and engaging devices including a platform and fingers conforming to the shape of a bottle, means for swinging said bottle receiving and engaging devices outwardly of the said rotating table and out of engagement with the said bottle engaging and label aflixing fingers, a series of cam actuated pivoted label receiving and conveying devices, each of which includes a bifurcated label receiving and conveying member, means for depositing paste on said member and means for depositing a label thereon to be conveyed thereby to one of said bottle engaging and label afiixing fin gers, said bifurcated label receiving and conveying member meeting and straddling the said bottle engaging and label afiixing finger to'deposit its label thereon while the said bottle receiving and engaging device is in an outwardly swung position, and means associated with each of said bottle receiving and engaging devices for swinging the same and its bottle inwardly of the said rotating table and into engagement with its said bottle engaging and label applying finger to receive a label therefrom.

17. A bottle labeling machine including a rotatable table, a series of bottle holding and engaging devices arranged thereon, a conveyer for conveying bottles to and from the said bottle holding and engaging devices, each of said bottle holding and engaging devices including a bottle engaging and label atlixing finger, a series of cam actuated label receiving and conveying devices, each of which includes a label receiving and conveying member to convey a label to one of said bottle engaging and label applying fingers, and means for effecting an engagement of a bottle in one of the bottle receiving and engaging devices with its said bottle engaging and label afiixing finger having a label thereon to receive said label therefrom, and means for wiping the label so received.

18. A bottle labeling machine including a rotatable table, a series of bottle holding and engaging devices arranged thereon, a conveyer for conveying bottles to and from the said bottle holding and engaging devices, each of said bottle holding and engaging devices including a bottle engaging and label aflixing finger, a series of cam actuated label receiving and conveying devices, each of which includes a label receiving and conveying member to convey a label to one of said bottle engaging and label applying fingers, and means for efiecting an engagement of a bottle in one of the bot-- tle receiving and engaging devices with its said bottle engaging and label aiiixing finger having a label thereon to receive said label therefrom.

19. A bottle labeling machine, including label so deposited on the bottle holding and enbgaging device, and means for wiping the la el.

20. A bottle labeling machine, including a bottle holding and engaging device, a cam actuated label receiving and conveying device for receiving and conveying a label to said bottle holding and engaging device to deposit the same thereon and means for efiecting an engagement of the bottle with a label so deposited on the bottle holding and engaging device.

21. A bottle labeling machine, including a bottle holding and engaging device which includes a movable bottle carrier and a relatively stationary bottle engaging and label aflixing finger, a label receiving and conveying device for receiving and conveying a label to said bottle engaging and label afiixing finger to deposit a label. thereon, means for moving said bottle carrier relatively to said bottle engaging and label afiixing finger for effecting an engagement of a bottle in said bottle carrier with a label so deposited on the bottle engaging and label atiixing finger and means for wiping the label.

22. A bottle labeling machine, including a bottle holding and engaging device which includes a movable bottle carrier and a relatively stationary bottle engaging and label aflixing finger, a label receiving and conveying device for receiving and conveying a label to said bottle engaging and label atfix ing finger to deposit a label thereon and means for moving said bottle carrier rehh tively to said bottle engaging and label ing finger for efitecting an engagement of a bottle in said bottle carrier with a label so deposited on the bottle engaging and label afiixing finger.

In testimony whereof, I aflix my signature, in presence of two witnesses.

JOHN J. GAYNOR.

"Witnesses:

G. M. Fonnnsr. C. HUGH DUFFY.